FREQUENTLY ASKED QUESTIONS

FAQs

Why is AquaGuard Engineered Coatings™ Considered Non-Toxic?

The main reason is there are ZERO VOC’s in our product. What are VOC’s? Volatile organic compounds (VOCs) are emitted as gases from certain solids or liquids. VOCs include a variety of chemicals, some of which may have short- and long-term adverse health effect as cancer, infections or poisons that lodge in the human body such as lead, mercury or arsenic among others., these are considered VOCs.

Is AquaGuard Engineered Coatings™ Suitable for Salt Water?

Yes – totally suitable for NaCl – We are also suitable for many other chemicals

Can AquaGuard Engineered Coatings™ be Painted?”

Yes AquaGuard Engineered Coatings™ is paintable – Only use exterior grade latex paints (waterborne) with 100% acrylic binders; this provides maximum adhesion. They are very flexible, so they continue to adhere even when temperature changes cause the surface and the rubber to expand and contract. This elasticity helps prevent chipping, peeling, flaking and other common paint failures.

How does AquaGuard Engineered Coatings™compare to other waterproof membranes ?

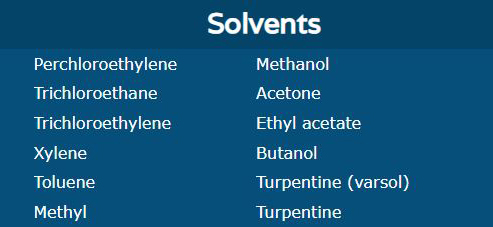

There are different types of coatings available on the market. AquaGuard Engineered Coatings™is water-based, non-toxic and contains zero VOC’s. This makes it easier to apply because there are NO solvents. Most solvents create fumes that require you to ventilate the room where the waterproofing membrane is being applied. This is not the case with AquaGuard Engineered Coatings™solutions. And because of this, our water-based product allows for work-safe applications and installations that, when applied correctly, will out perform solvent based competitors

Can AquaGuard Engineered Coatings™ be applied to vertical surfaces?

Yes, AquaGuard Engineered Coating™ can be applied to both vertical and overhead surfaces.

Is AquaGuard Engineered Coatings™ safe for potable water?

Yes, in applications where the water storage tank exceeds 500 gallons in capacity this product can be used to stop corrosion on the inside of your water tank – with the additional benefit that the annual maintenance cost of cleaning your water storage tank is significantly reduced, and you have stopped the potential replacement due to corrosion. In applications where AquaGuard Engineered Coatings™ is used to hold and contain water, apply at a thickness of 60mil – this is typically three generous coats of Universal Grade. Unlike polyurethane base products, AquaGuard Engineered Coating™ will not “pin hole” – this is due to the self healing nature of our product.

Is protective equipment necessary when applying AquaGuard Engineered Coatings™?

To put it simply – NO. However, common sense should always be used when applying any type of coating product. Whether spraying or rolling/painting it on, we do recommend protective eye-wear and latex gloves at a minimum. We also recommend wearing clothing you don’t mind messing up. Once the Liquid Rubber dries and vulcanizes, it is very difficult to remove from unwanted areas – so proper preparation of surrounding areas is necessary.

How long does it take AquaGuard Engineered Coatings™ to dry?

This depends on relative humidity and how AquaGuard Engineered Coatings™ is applied:

When AquaGuard Engineered Coatings™ is applied utilizing the dual channel sprayer a) drying until “tack” is less than 1 minute, b) surface drying takes approximately 2 hours, c) deep drying – 24 to 72 hours and d) it completely vulcanizes in 2 to 7 days. These times are considerably reduced during the warm summer months. Tt is recommended, when possible, to allow AquaGuard Engineered Coatings™ to dry in direct sunlight.

When AquaGuard Engineered Coatings™ is applied with a brush or roller – drying times are the same as above, with the exception of “tack” and surface drying – this will take from 30minutes to 3 hours. Again, dry and cure times are considerably reduced when applied in the summer months and the product is allowed to dry in direct sunlight.

Because AquaGuard Engineered Coatings™ is water-based, drying times are dependent on humidity. The above times are based at 55% relative humidity. AquaGuard Engineered Coatings™ must not be applied in open spaces with high rain probability.

Is AquaGuard Engineered Coatings™ environmentally friendly?

Yes – Because AquaGuard Engineered Coatings™ is water-based, non-toxic contains zero VOC’s it is considered a “Green” product. It meets Ecological Safety quality of EU and RF (SRN 2.2.4.1074-01, SRN 2.1.2.1188-03).

How do I apply AquaGuard Engineered Coatings™?

AquaGuard Engineered Coatings™ can be applied in a variety of manners:

• Rolled-On

• Brushed-On

• With Squeegee or Trowel

• Sprayed-On – with our DSPP or our Pump System