PROJECTS

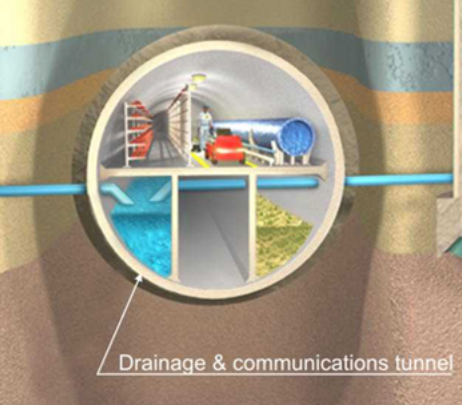

Communication Tunnel (ASHGABAD)

The Challenge:

• Lowering of groundwater level in most flooded areas of the city.

• Collection and transport drainage water and sewage outside the boundaries of the city.

• Installation of utilities – water pipes, electrical cables, low-voltage lines inside the tunnel.

Information

• Tunnel construction is carried out under complex hydro geological conditions in the city with already developed system of communication .

• Seismicity of the area – up to 10 points

• The length of the tunnel with the outer diameter of 6m – 16.5km.

• The length of the tunnel with the outer diameter of 3.5m – 13.82km.

• There are 31 Construction Chamber which were constructed by the method of “wall in the ground”.

Wastewater Treatment Plant

The Challenge: The concrete tanks were extremely fractured as improper construction caused failures in the concrete

Four separate concrete tanks were coated for the customer. Each tank contains liquid and solid swine manure; which is extremely acidic and corrosive.

AquaGuard Engineered Coatings™ Universal Grade Coatings was used on the seams, large cracks and voids. Industrial Grade was them spray applied at an 80 mil (2mm) thickness.

No degradation to the coating has occurred from the harsh Hydrogen Sulphide attack. Project is still performing exceptionally well.

Solution

Under Slab Waterproofing & Methane Barrier Protection: AquaGuard Engineered Coatings™ was specified in to be a waterproof layer below the concrete slab & also had to be a methane barrier in areas where methane levels were high.

Industrial Grade was sprayed on top of pre-cut geotextile at an 80mil (2mm) thickness. The geo-textile had to be cut and placed around the 200 plus penetration on some of the slabs.

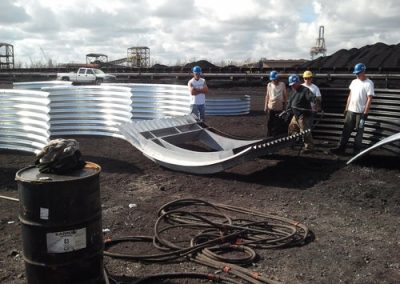

Aquaculture Farming Tanks

The Challenge: to Protect Aqua Culture Tanks from Corrosion & Fouling using environmentally safe sealant

A Norwegian ocean based salmon farm needs to preserve their aquaculture tanks from the marine environment that provides a host of chemical, biological and physical challenges to their materials over time.

• To protect ocean exposed farm assets by increasing the longevity and durability of the aquaculture tanks.

• Reduce the corrosive effect of salt water, ultra violet rays & marine organisms.

• Seal tank exteriors against leakage.

• Ensure environmental protection by using a proven non-toxic coating product

Solution

Application of AquaGuard Engineered Coatings™ Industrial Grade provides exterior hull preservation and acts as an anti-corrosion sealant. It’s water-proof coating protects surfaces against salt, ultra violet rays, abrasion and corrosion. The product also reduces fouling by providing a low tension, non adhesive surface that prevents the undesirable build-up of microorganisms, plants, algae such as barnacles, seaweeds, molluscs and zebra-mussels .

And by using AquaGuard Engineered Coatings™Universal Grade Coatings used on the seams, tanks will be protected against potential future leakage.

AquaGuard Engineered Coatings™ are effective in protecting against marine-related damage while meeting increasingly strict marine environmental regulations such as the the international treaty that banned 12 of the most persistent toxic organic pollutants. Our product is non-toxic, non-hazardous, free of V.O.C.s (Volatile Organic Compounds) and contains no harmful solvents.

CAPITAL UNITED

Underground construction

Tunnels

Infrastructure projects

Collectors System for dewatering

(Under construction)